Precise product marking is a key element of identification, branding, and aesthetics. At BOTT, we specialize in modern printing techniques that ensure high durability, abrasion resistance, and excellent detail quality. Thanks to advanced technologies, we can apply markings to a variety of materials.

We offer a range of printing methods tailored to the specifics of each product and customer expectations. We use screen printing, pad printing, hot stamping, inkjet and laser marking, which allows us to execute both simple markings and complex graphics or serial codes.

The choice of the appropriate printing technology depends on many factors, such as the type of surface, level of pattern detail, resistance to external factors, and aesthetic requirements. Our experience and modern technological facilities enable us to complete even the most demanding projects, ensuring durable and legible markings.

Discover the details of each printing method and choose the solution that suits your needs!

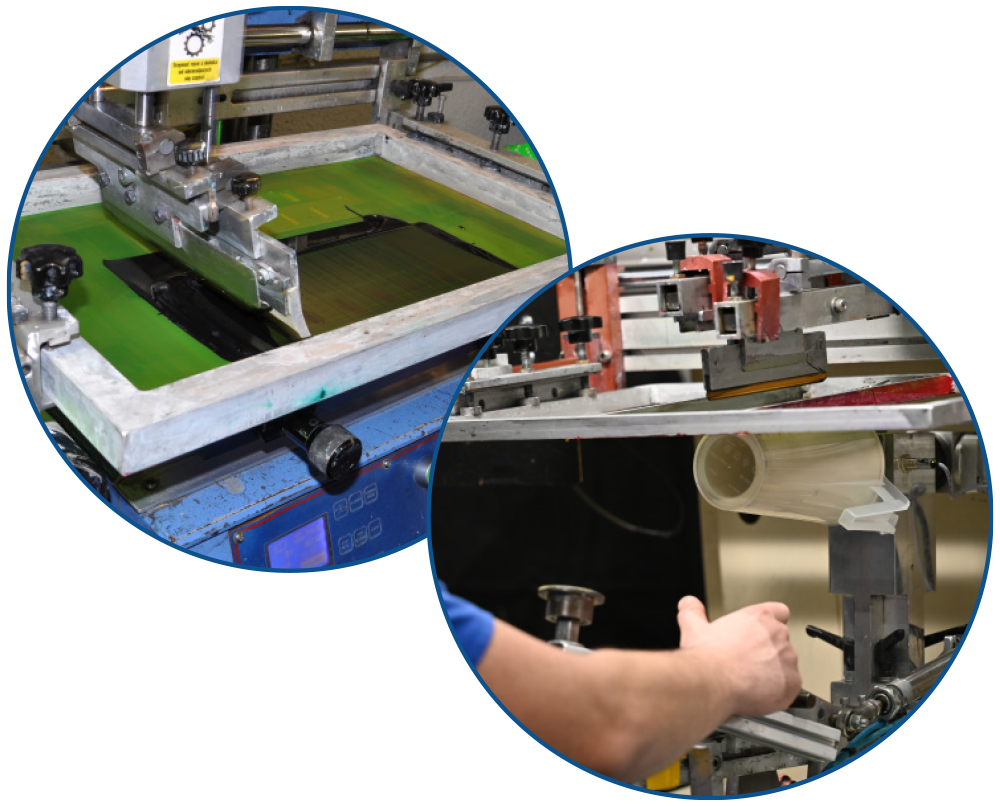

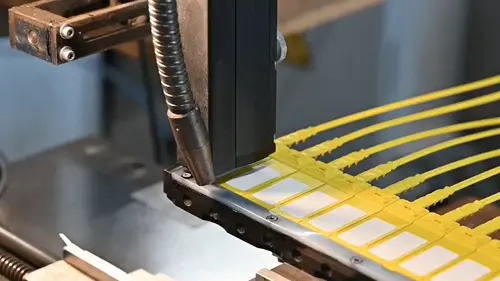

Screen printing, also known as silk-screen printing or serigraphy, is a printing technique where the printing form is a stencil applied to a fine mesh made of synthetic fibers. The print is created by pressing ink through the mesh, ensuring accurate pattern reproduction.

Screen printing is the only method that allows exceptionally durable prints on plastics. It is one of the oldest and most effective techniques used to transfer vivid designs onto various surfaces. With this method, we can reproduce even the most complex graphic projects, offering intense and long-lasting colors.

Due to its reliability and resistance to weather and chemicals, screen printing is widely used in industries such as agriculture, chemicals, construction, and food.

Our screen printing inks are highly durable – resistant to chemicals, abrasion, and dishwasher washing. This ensures that the prints maintain their quality even in the most demanding usage conditions.

Screen printing offers unlimited possibilities in terms of color and allows printing on virtually any surface – flat or curved, regardless of size. It’s a perfect solution for companies seeking aesthetic, durable, and resistant markings for their products.

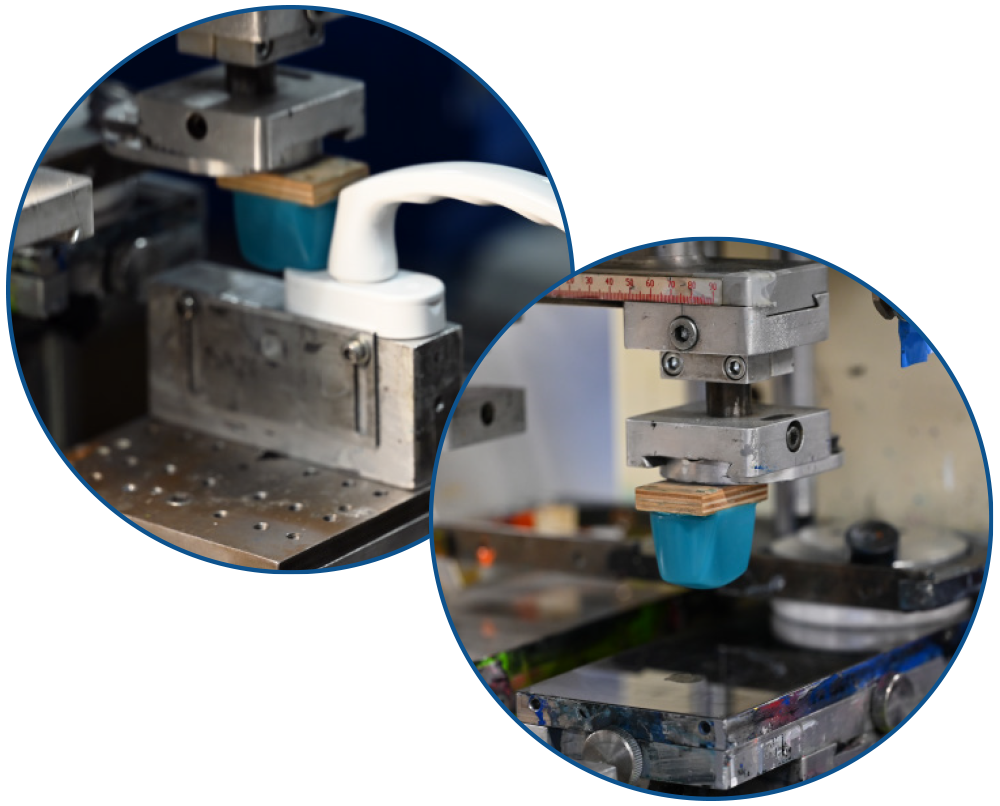

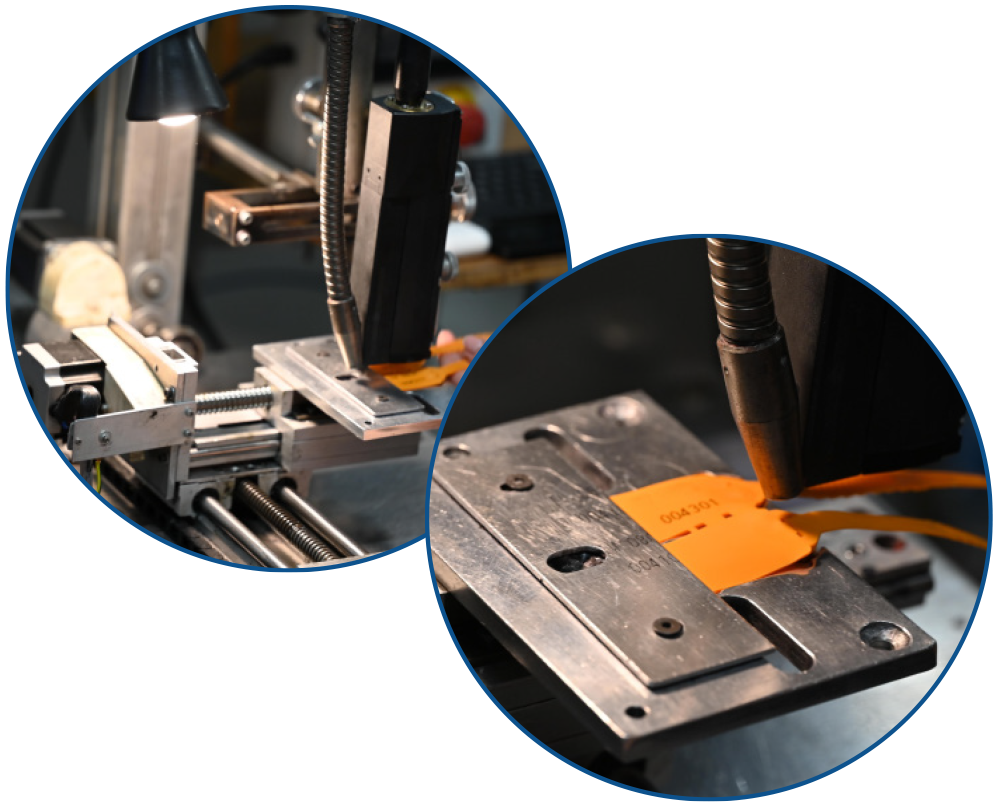

Pad printing is a method for durable and fast printing on plastic materials, ideally suited for the agricultural, chemical, construction, and food industries. This technique involves transferring ink with the help of a soft, smooth silicone stamp called a pad. It is ideal for marking small items with flat or slightly curved surfaces where precision and detail clarity are essential.

This technique is especially recommended for items requiring limited color usage, offering sharp and resistant markings. Thanks to the use of high-quality inks, pad-printed markings are resistant to abrasion and external influences.

Hotprint, also known as hot stamping, is a single-color printing technique using a heated die. It is a dry printing method that utilizes special foil. The process involves embedding a design and a layer of pigment from a colored foil into the surface of the product. The result is a permanent print, often with a subtle embossed effect.

Hotprint is especially recommended for metallic colors such as gold or silver, but other colors can also be used. The main advantages of this method include the durability of the print, its abrasion resistance, and an elegant, luxurious appearance. It’s a fast, durable, and visually appealing printing solution.

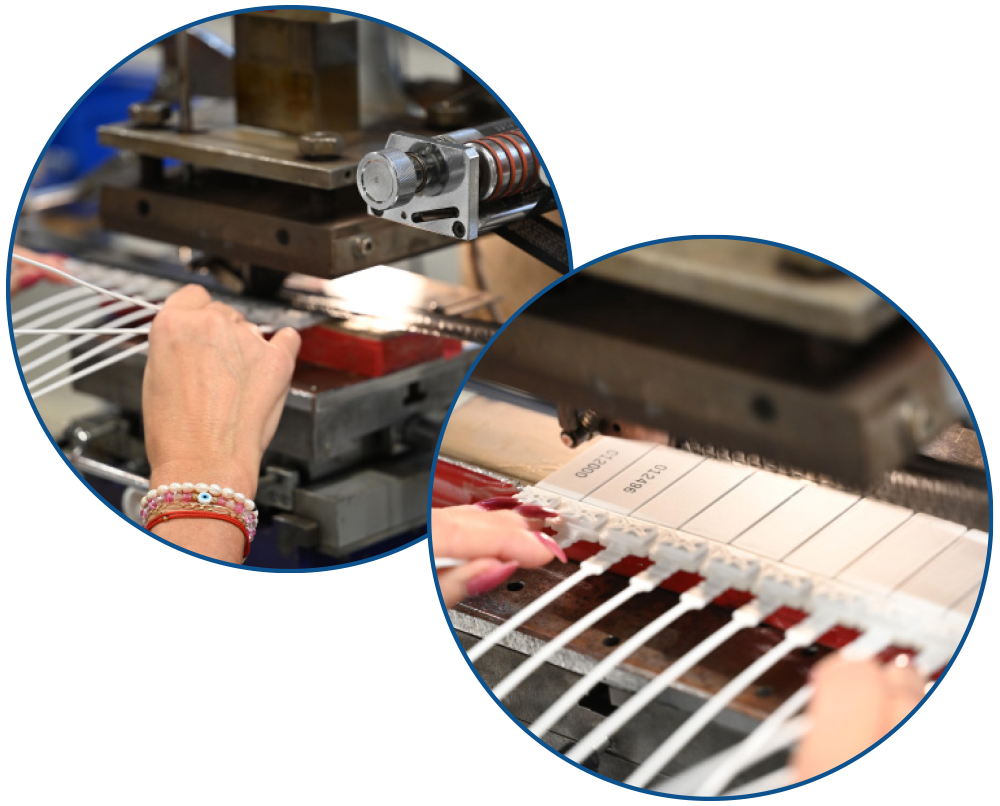

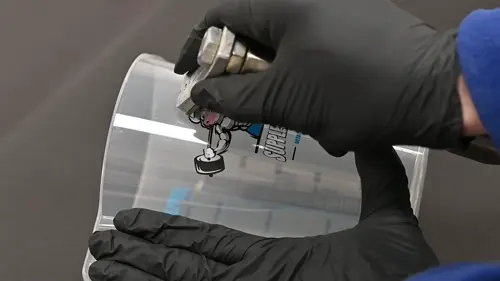

Inkjet is a modern, contactless method of marking various material surfaces. It involves spraying ink onto a moving product, making it an extremely efficient and versatile printing technique.

This technology allows for the permanent application of text, variable numbering, barcodes, and QR codes. Inkjet printing is widely used in logistics, the food, pharmaceutical, and construction industries, where quick and precise product marking is essential.

One of the main advantages of inkjet printing is its flexibility – it can be used on nearly any surface. Additionally, thanks to the use of modern inks, the prints are highly resistant to abrasion and external factors.

Laser marking, also known as laser engraving, is an advanced technology enabling precise and permanent marking of various materials, including plastics. This process uses a laser beam that, through concentrated energy in a small point, thermally modifies the surface of the material.

This technique creates extremely durable markings that resist abrasion, chemicals, and weather conditions. Due to the high precision of laser printing, it can be used for marking both small details and large surfaces, making it a highly versatile method.

Laser marking enables product personalization by adding logos, serial numbers, barcodes, QR codes, and other identifiers. It is widely used in the electronics, automotive, medical, and advertising industries.

Another benefit of laser printing is its eco-friendliness – it requires no inks or additional chemicals, making it safe for the environment.

We test print adhesion according to the following standards:

ISO 2409 and ASTM D3359-B / DIN 53151.

Print abrasion resistance is tested according to: ASTM D5264.

NIP: PL 6972314982

Sylwia Szymyślik